VT-SF

(Chemically Accelerated Super Finishing) of high-performance engine and gear train components to low micron finishes. Parts

such as crankshafts, camshafts, crown wheels, pinion gears and long shafts etc.

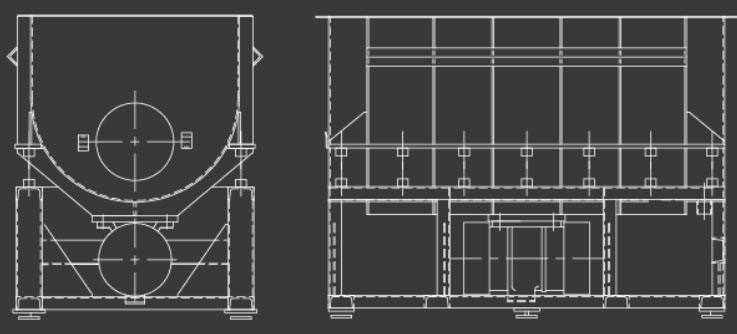

Vibratory Trough Machines

The machine is a steel fabricated and polyurethane lined construction with all process contact parts manufactured for 316 stainless steel to withstand the chemistry required from the isotropic superfinishing process. The machine is supplied complete with all major fixtures and fittings as parts are generally mounted between rotating centres to ensure uniformity of finish and maximum protection

More Information

Technical Specifications

| Model | Trough Section (wxdxl mm) |

|---|---|

| VT2 | 400 x 450 x 500 |

| VT5 | 400 x 400 x 800 |

| VT7 | 400 x 400 x 1000 |

| VT9 | 550 x 550 x 1000 |

| VT10 | 600 x 600 x 700 |

| VT12 | 450 x 450 x 1250 |

| VT15 | 500 x 550 x 1250 |

| VT16 | 600 x 600 x 1500 |

| VT20 | 750 x 700 x 1475 |

| VT25 | 600 x 650 x 2250 |

Bench mark example

Finishing high value heavy items such as crankshafts, camshafts, rim centres and the like, has never been easier with the recent development in our VT range. Our stainless steel fixturing system offers support as well as protection for achieving high level of surface treatment.

Send us an email with a

description of your application

and finishing requirements

Free Sample Trials

Send some sample pieces

for our free sample trials

Quote

We’ll send back a

recommendation of surface

finishing equipment and

consumables

Supply

If the results are right,

we’ll supply a finishing system along

with a step by step instruction manual

and a fully documented process report sheet